CANVASA

Click the QR code and bring the Canvasa virtually into your production area

Innovative

Filling Technology

The increasing demand for Made-In-Germany microfillers led us to launch Canvasa. As one of the leading innovators, we developed the world’s most compact can filler with patented counter pressure technology.

The can filler has the footprint of a standard Euro pallet, so it can be used anywhere, anytime.

The Canvasa is a compact, semi-automatic can filling machine. The newly developed and patented counter-pressure filling technology allows carbonated and non-corbonated products to be filled gently and with minimal oxygen input.

Accessories such as a depalletizing table, automatic rinser, labeler, etc., allow the Canvasa to be converted into a small, economical and fully automatic “mini line”.

The machine can process all common can formats standard, sleek or slim The Canvasa is the ideal entry-level model, especially for small start-ups or beverage producers who initially want to “try out” cans.

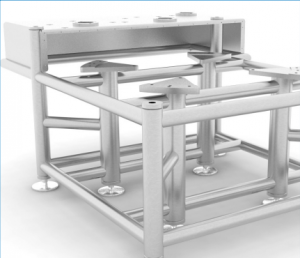

Due to its open construction we comply with the basic idea of the Hygienic design. Leibinger fillers are all designed and built as mechanically as possible so that the recommended annual maintenance service can be carried out by an experienced technician.

You can also inquire about leasing options for this model.

TYPE

Canning Machine

TECHNOLOGY

counter pressure

filling valve

STATIONS

2

PRODUCTS

all beverages

OUTPUT RANGE

360 – 1,200 cph

O2 PICKUP

10-60 ppb

Filling valve

Hand rinser

HPI Heater

HPI

Frame

Seamer

Panel

More features

Construction

Due to its compact design, the Canvasa fits on a standard Euro pallet and is suitable for mobile use due to its castors.

CIP

Our filling machine is CIP capable. Due to the closed circuit with dummy cans and the gasket materials used, the machine can be cleaned with both acid and alkaline concentrations.

Booster pump

The booster pump is responsible for increasing the water pressure and compensating for possible fluctuations in in-house water pressure. It provides a permanently constant water pressure for the HDE and this can be adjusted via the panel.

Key Facts

The HPI heater is used to provide a continuous HPI supply of hot water at a minimum of 80°C. This makes the HPI water bacteria-free.

The specially developed seamer ensures proper sealing of the can lids. Each machine is checked for a standard-compliant closure before leaving the factory.

The Leibinger base frame eliminated as many horizontal surfaces as possible, allowing excess water or product to drain away at all times. This complies with the idea of the Hygienic Design.

Due to its compact design, the Canvasa fits on a standard Euro pallet and is suitable for mobile use due to its castors.

Our filling machine is CIP capable. Due to the closed circuit with dummy cans and the gasket materials used, the machine can be cleaned with both acid and alkaline concentrations.

Our Siemens-based control system can be operated intuitively, similar to a smartphone. The machine can be operated via the HOME button.

The booster pump is responsible for increasing the water pressure and compensating for possible fluctuations in in-house water pressure. It provides a permanently constant water pressure for the HDE and this can be adjusted via the panel.

RINSE

FILL

CAP

Options

Automatic rinser

The automatic rinser rinses the cans and removes any residues. This prepares the containers for filling.

Semi-automatic depalletizer

The depalletizing table allows semi-automatic depalletizing of half can pallets. These are lifted to the appropriate height using a pallet truck or forklift and transported to the turntable using a pusher. The turntable then automatically carries the cans to the automatic rinser, which is available on request.

Rotating collecting table

The collection table is a small rotating table that holds the cans at the outlet of the Canvasa, so they don’t require to be removed manually. This can be used instead of the labeler or conveyor belt.

Self-adhesive labeler (Company: GERNEP) – label date printer

From the company Gernep we offer a small labeler, which applies self-adhesive labels to all common can formats.

Date Coder for can bottom

For printing the can bottom with best-before date or tracking number (Company: Paul Leibinger GmbH & Co. KG). Only in combination with the automatic rinser.

Booster pump for HPI

The booster pump is used to increase the pressure or to counteract possible pressure fluctuations.

Technical Details

Rated power

360 – 1,200 cph (Standard, Sleek or Slim cans)*

Conveyor belt height

PLC

Siemens

Connected load

230 V / 50 Hz**

Seamer

Leibinger

End seaming tool

Leibinger

Filling valve axle

Festo

Drive units

Siemens / SEW

Hygienic Design

A round tube frame instead of conventional table plate.

*product specific **country specific

Container (Bottle/Can) and Fill Level

Adjustment through exchange of:

Filling tubes

Container guiding parts

Centering bells

Materials

Mainly used materials:

Stainless steel (1.4571 or 1.4404)

Food safe plastics (z.B. POM or PTFE)

Food safe elastomer (z.B. EPDM)

Piping in stainless steel (1.4404)

Reliability

Components are predominantly mechanical, which provides easy maintenance and a long service life.

Saving labor cost

To reduce labor costs pre-installed programs are available for:

Automatic operation

CIP cleaning

Safety housing

The doors consist of frameless safety glass (Makrolon). All machine areas are accessible through safety doors or removable covers.

Further characteristics

All guiding stars secured by central friction clutch

Mechanical lifting cylinders

Integrated conveyor belt through the full course of the machine

Designed for CIP cleaning

Central lubrication system

User friendly operating panel (HMI)

Complies with all CE requirements at the date of shipment

Hygienic Design®

Our Hygienic Design® concept eliminates as many horizontal surfaces as possible.

The result: a round tube construction as a replacement for the classic table top.

Downloads

Layouts

Inquire about CANVASA

We are looking forward to helping you! Please use the contact form for general requests and the inquiry form, if you´d like to get detailed information about our filling machines.

WHEREVER YOU ARE

Leibinger Remote Service

With the Leibinger Remote Service we can remotely help you to repair your machines yourself.