TRANSVASA

Transvasa

Transvasion machine

Gentle

transvasing

The TRANSVASA is designed for emptying glass bottles. Each emptying station is designed as a counter pressure valve with a long tube. Flexible hoses are installed on top of the emptying tubes in order to reach the bottom of the bottle The “blow empty” principle using gas (e.g. CO2) prevents the release of the products’ CO2. The product is captured and settled in a pressure tank and conveyed further automatically by the included pump.

Due to the largely mechanical design, simple maintenance by the machine operator can be performed. Furthermore, this guarantees a long service life. By exchanging bottle guidance parts, different bottle formats can be used in the machine. Depending on the size, the changeover time is between 10 and 30 minutes.

Due to its open construction the Transvasa complies with the basic idea of the Hygienic design. All machines can be specified as left or right-turning.

TYPE

Transvaser

TECHNOLOGY

counter pressure

long tube

STATIONS

6

12

18

24

30

PRODUCTS

Sparkling wine, champagne

OUTPUT RANGE

800 – 8,000 bph

Frame

Bottle stop

Carousel spraying

Decapper (tear off wheel)

Residual remover

Buffer tank

More features

Manufacturing

Our machines are 100% assembled in our own factory. The materials used are predominantly made of stainless steel and food-grade plastics and elastomers. We take care to consult only local manufacturers and thus further strengthen the economy of our location.

CIP

The Transvasa is CIP capable. It is possible to clean the machine with acid and alkali concentrations as well as with steam thanks to a closed circuit system equipped with rinsing caps and sealing materials.

Panel

Our Siemens-based control system can be operated intuitively, similar to a smartphone. The machine can be operated via the HOME button.

Safety housing

We use a free-standing safety enclosure made of frameless non-splintering safety glass (Makrolon). All machine areas are accessible through electrically and mechanically secured doors.

Operating direction

Our machines can all be ordered as left- or right-running, and thus fit into any line planning.

Key Facts

The bottle stop prevents further bottles from running in after the filling process has been stopped in the normal way. This prevents open, filled bottles from remaining in the filler carousel. The filler runs empty.

The bottle stop prevents further bottles from running in after the filling process has been stopped in the normal way. This prevents open, filled bottles from remaining in the filler carousel. The filler runs empty.

Carousel spraying is used for the short-term removal of e.g. sticky product residues or broken fragments. The production itself is seldom interrupted.

Carousel spraying is used for the short-term removal of e.g. sticky product residues or broken fragments. The production itself is seldom interrupted.

Optionally, a breakaway wheel can be added for the bottles to be emptied. This ensures that the bottle corks are removed cleanly before the bottle is emptied.

Optionally, a breakaway wheel can be added for the bottles to be emptied. This ensures that the bottle corks are removed cleanly before the bottle is emptied.

Our drain valves are developed exclusively mechanically. This ensures a long service life on the one hand, and on the other hand allows the machine operator to intervene or repair the machine at any time without a service technician.

Our drain valves are developed exclusively mechanically. This ensures a long service life on the one hand, and on the other hand allows the machine operator to intervene or repair the machine at any time without a service technician.

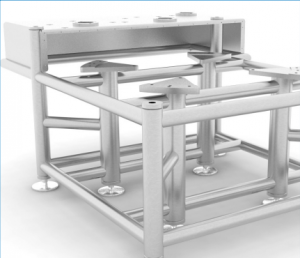

The Leibinger base frame eliminated as many horizontal surfaces as possible, allowing excess water or product to drain away at all times. This complies with the idea of the Hygienic Design.

The Leibinger base frame eliminated as many horizontal surfaces as possible, allowing excess water or product to drain away at all times. This complies with the idea of the Hygienic Design.

Part of the machine is a pump-controlled buffer tank into which the product is conveyed and allowed to settle.

Part of the machine is a pump-controlled buffer tank into which the product is conveyed and allowed to settle.

Our machines are 100% assembled in our own factory. The materials used are predominantly made of stainless steel and food-grade plastics and elastomers. We take care to consult only local manufacturers and thus further strengthen the economy of our location.

The Transvasa is CIP capable. It is possible to clean the machine with acid and alkali concentrations as well as with steam thanks to a closed circuit system equipped with rinsing caps and sealing materials.

Our Siemens-based control system can be operated intuitively, similar to a smartphone. The machine can be operated via the HOME button.

We use a free-standing safety enclosure made of frameless non-splintering safety glass (Makrolon). All machine areas are accessible through electrically and mechanically secured doors.

Our machines can all be ordered as left- or right-running, and thus fit into any line planning.

EMPTY

Options

Decapper (tear off wheel)

Residual remover

Technical Details

Rated power

800 – max. 8,000* bph (750 ml)

Conveyor belt height

Product temperature

max. 20°C

Connected load

400 V / 50 Hz / 3 Ph**

Drive unit

0.37 – 1.5 kW

Hygienic Design

A round tube frame instead of conventional table plate.

*product specific **country specific

Container (Bottle/Can) and Fill Level

Adjustment through exchange of:

Filling tubes

Container guiding parts

Centering bells

Materials

Mainly used materials:

Stainless steel (1.4571 or 1.4404)

Food safe plastics (z.B. POM or PTFE)

Food safe elastomer (z.B. EPDM)

Piping in stainless steel (1.4404)

Reliability

Components are predominantly mechanical, which provides easy maintenance and a long service life.

Saving labor cost

To reduce labor costs pre-installed programs are available for:

Automatic operation

CIP cleaning

Safety housing

The doors consist of frameless safety glass (Makrolon). All machine areas are accessible through safety doors or removable covers.

Further characteristics

All guiding stars secured by central friction clutch

Mechanical lifting cylinders

Integrated conveyor belt through the full course of the machine

Designed for CIP cleaning

Central lubrication system

User friendly operating panel (HMI)

Complies with all CE requirements at the date of shipment

Hygienic Design®

Our Hygienic Design® concept eliminates as many horizontal surfaces as possible.

The result: a round tube construction as a replacement for the classic table top.

Downloads

Layouts

Request TRANSVASA

We are looking forward to helping you! Please use the contact form for general requests and the inquiry form, if you´d like to get detailed information about our filling machines.

WHEREVER YOU ARE

Leibinger Remote Service

With the Leibinger Remote Service we can remotely help you to repair your machines yourself.